Encoder Basics

Encoders provide motion control information on position, count, speed and direction. As the encoder shaft rotates, output signals are produced, proportional to the distance (angle) of rotation. The signal may be in the form of a square wave (for an incremental encoder) or an absolute measure of position (for an absolute encoder). Due to the performance and reliability advantages of the semi-conductor technology they incorporate, optical encoders are the preferred solutions in many common computer, industrial and automotive applications. Optical encoders also benefit from ease of customization, are suitable to numerous environments, and suffer no effects from high levels of stray magnetic fields.

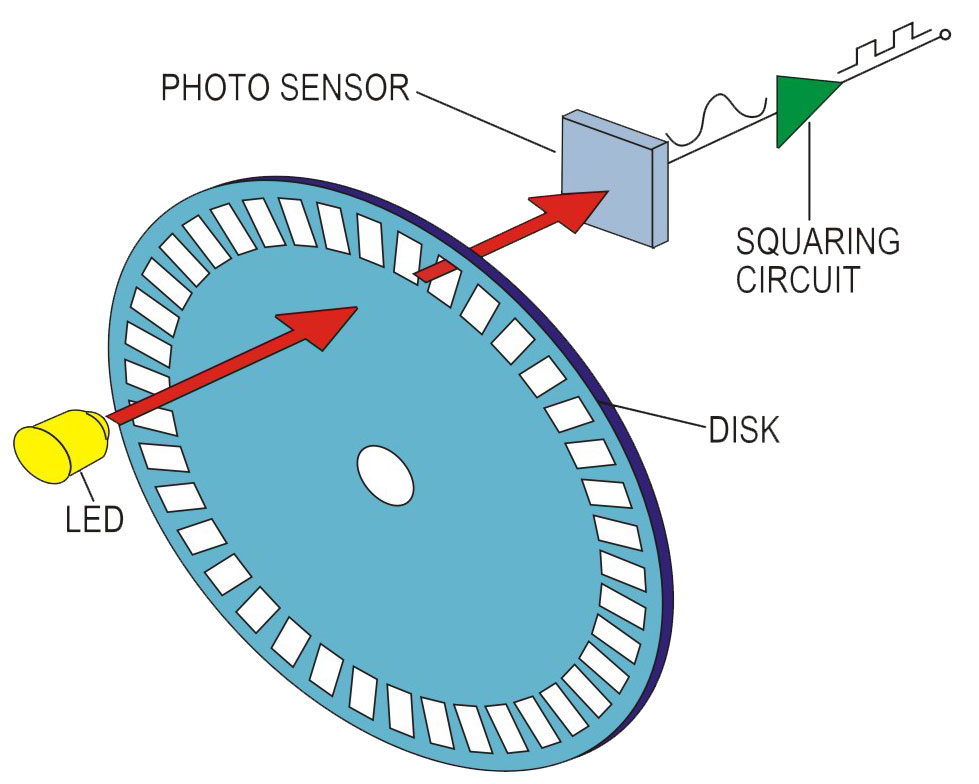

The basic construction of an incremental encoder is shown to the left. A beam of light emitted from an LED passes through a transparent disk patterned with opaque lines and is picked up by a photodiode array. The Photodiode array (also called a photo sensor) responds by producing a sinusoidal waveform which is transformed in a square wave or pulse train. Incremental encoder, often called a tachometer, is normally used in systems that rotate in one direction only and require simple position and velocity information. Quadrature encoders have dual channels ( A and B ), phased 90 electrical degrees apart.

These two output signals determine the direction or rotation by detecting the leading or lagging signal in their phase relationship.

Quadrature encoders provide very high speed bi-directional information for very complex motion control applications. Incremental encoders can provide a once-per-revolution pulse (often called index, marker, or reference) that occurs at the same mechanical point of encoder shaft revolution. This pulse is on a separate output channel (Z) from the signal channel or quadrature outputs. The index pulse is often used to position motion control applications to a known mechanical reference. Resolution is a term used to describe the Pulses Per Revolution (PPR) for incremental encoders, or the total number of unique positions per revolution for an absolute encoder. Each incremental encoder has a defined number of cycles that are generated for each full 360 degree revolution. These cycles are monitored by a counter or motion controller and converted to counts for position or velocity control. Absolute encoders generate a unique code word for every resolvable shaft angle (often called bits or pulse per revolution).

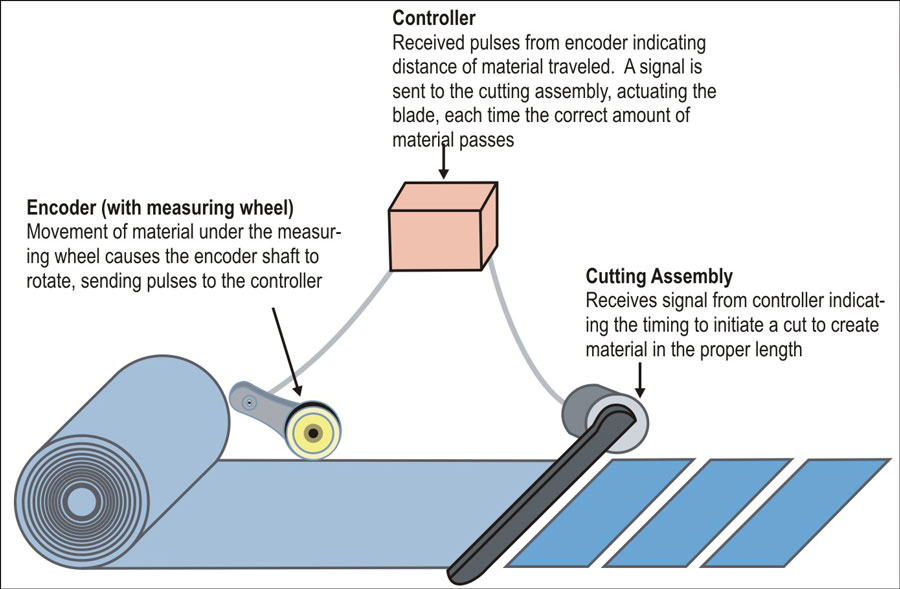

Motor feedback is the most common use for rotary encoders. In this type of application, an encoder is either mounted directly to the motor, or indirectly using a measuring wheel or chain-and-sprocket arrangement. The parameter of interest is primarily the speed of the motor. Web tensioning is an application in which the encoder is not usually mounted to the drive motor, but to one of the tensioning arm rollers. Any unevenness in the speed of this roller indicates that proper web tension is not being maintained and must be adjusted. The rotating speed of the tensioning roller is fed back to the controller, which then adjusts the drive motor so that web material is kept at an even tension. Cut-to-Length is a very practical application of an encoder combined with simple mathematics. If, for example, a system were to be designed with a roller that is exactly one foot in circumference, the roller would feed one foot of material for every revolution of the roller. An encoder mounted to the roller would reflect this situation and could tell a controller how much material had been fed through the roller. The resolution of the encoder would also directly reflect the accuracy of the cut. In the above example, 96 PPR would yield cuts to an 1/8" accuracy. Elevators are just one example where encoders can perform a dual role. They can determine the position of the elevator through elevator.

In Backstop Gauging the encoder is used to make sure that the unit, typically a machine tool, does not exceed a preset position or direction of travel. Very often, this is combined with a determination of the speed of travel of the table, tool head, or similar component. Filling applications is just one example where Table Positioning is critical since the item being filled must arrive at filling tube at the same time the fluid control is turned on. Conveying is another common industry where encoders are widely used. They may be attached to the motor, to intermediate axle shafts, or to both. Encoders are an especially effective feedback device where the positioning and/or speed of multi-element conveying systems must be carefully coordinated. Spooling (sometimes referred to as Level Wind) is another application where encoders can prove invaluable. Not only is it necessary that the speed of the supply and take-up reels be kept in proper relation to each other, but the amount of material being spooled must also often be tracked. Electronics is just one industry that widely uses encoders in Pick and Place applications. Here many of the capabilities of Encoders(rate, position, speed, velocity)can often be found combined in single system.

Rotary Optical Encoders: Enhancing Precision in Industrial Applications

Rotary optical encoders are critical components used in various industrial applications that require precise measurement and control. These sophisticated devices provide accurate feedback on rotational movement, enabling machinery to operate with exceptional precision. In this article, we will delve into the world of rotary optical encoders, exploring their types, applications, benefits, and more. So, let's get started!

In the realm of industrial automation and control, the demand for high-precision measurement systems is ever-growing. Rotary optical encoders play a vital role in meeting this demand by providing accurate position and speed feedback in rotational applications. Whether it's a CNC machine, robotic arm, or printing press, rotary optical encoders ensure precise control and reliable operation.

Types of Rotary Encoders

-

-

Rotary Shaft Encoders

-

Rotary shaft encoders are the most common type of rotary encoders. They are directly mounted on a shaft and detect its angular position. These encoders are available in both incremental and absolute versions, offering different levels of precision and functionality.

-

-

Absolute Encoders

-

Absolute encoders provide a unique digital code for each position on the disk, enabling precise position feedback without the need for a reference point. These encoders offer excellent accuracy but are generally more expensive than incremental encoders.

-

-

Incremental Encoders

-

Incremental encoders measure relative changes in position and require a reference point to establish an absolute position. They are widely used in applications where cost-effectiveness and high resolution are crucial. Two common types of incremental encoders are incremental optical encoders and magnetic encoders.

-

-

Incremental Optical Encoders

-

Incremental optical encoders employ light patterns on a disk to encode position changes. They are known for their high resolution, compact size, and compatibility with various industries and applications.

-

-

Magnetic Encoders

-

Magnetic encoders, as the name suggests, use magnetic fields to encode position changes. They are highly resistant to environmental factors such as dust, moisture, and vibrations, making them suitable for challenging industrial environments.

-

-

Hollow Shaft Encoders

-

Hollow shaft encoders feature a hollow centre, allowing the encoder to fit over an existing shaft or pass through it. These encoders are often used in applications where space is limited or where the installation process needs to be simplified.

-

-

Solid Shaft Encoders

-

Solid shaft encoders are mounted directly onto a solid shaft, providing a compact and reliable solution for position sensing. They are widely used in various industrial applications, such as robotics, machine tools, and automation systems.

-

-

Programmable Encoders

-

Programmable encoders offer flexibility in terms of resolution and output signals. They allow users to configure various parameters, such as resolution, output type, and electrical interface, to match the specific requirements of their application.

-

-

High-Resolution Encoders

-

High-resolution encoders are designed to provide extremely precise position feedback. These encoders offer finer resolution and enable more accurate control in applications that demand exceptional precision, such as semiconductor manufacturing or scientific instrumentation.